The Czech Republic is home to many notable traditional crafts and its cultures. However, in this article, we will look at the history of metal buttons in the Czech Republic, which have not been well-known until now.

Czech metal buttons first appear in history around 1770, when records show that the first tin buttons were made in the border region between the Czech Republic and Germany. The first metal buttons started about 250 years ago. In this area, which was inhabited by many Germans as well as Czechs as we know it today, the first tin button was made by a man called Christian Hieke, who lived in Petrovice. Later, in 1783, the Winkler brothers founded the first button-making workshop. At the time, they had no idea that this button-making business would later become world-famous.

目次

Production gradually moved from Petrovice to Tyssa in what is now Bohemia, where the history of Czech metal buttons began in earnest. Already at the beginning of the 19th century, decorative buttons from Tyssa could be seen everywhere in these cities – Prague, Berlin, Paris and Milan. From that time onwards, all over Europe, Bohemian metal buttons gained a reputation for quality and taste amongst the Czech aristocracy and the Parisian salons. Apprentices trained in the first workshops gradually became skilled craftsmen, and Bohemian buttons were spread throughout Europe by them.

By the end of the 19th century, records show that some 800 craftsmen were already producing fine buttons in 68 small workshops, many of which were family-run.

Gradually, production was modernised and the range of buttons expanded. In addition to common non-metallic buttons, popular items included cufflinks, coloured buttons and chest buttons, which are the template for the present day.

・The advent of war

This was a time when buttons made of Tyssa were gaining in popularity. To the surprise of all, Bohemian metal buttons were adopted by all European armies, and not only that, they were even used in the uniform of the Kingsguard of the Ethiopian Emperor Haile Selassie. But war would rob everyone of their peace.

The First World War brought with it a shrinking market and unemployment. But the button manufacturers in Bohemia managed to cope with the difficult economic situation. And the range of products manufactured in Tyssa varied from glove buttons, hairpins, hooks, fittings for braces, screws, umbrella parts, etc.

The start of the Second World War dealt a further painful blow to production: in 1938, production was forced to cease and it was very difficult to survive the post-war period. Severe damage to the production process, shortage of materials… The state took over the management of production from the German owners.

By the end of 1945, 15 of the then existing companies had resumed production, and jewellery and glass artisans from Jablonec, a jewellery and glass town close to Tyssa in the northern Czech Republic, also came to Tyssa. It is also said that at that time there were more than 250 button manufacturers worldwide, dozens of which were interested in Tyssa and its high technology.

・The KOH-I-NOOR era – the post-WWII state enterprise system

In the years following the Second World War, individual companies gradually began to be merged under the Central State Committee. Some of them disappeared and the rest were merged into the newly founded KOH-I-NOOR Děčín in 1950. Tyssa did not only produce buttons, but also metal parts and metal chains for uniforms, which were made in Jablonec nad Nisou.

At that time, buttons made in Tyssa attracted great interest from all over the world. The Tyssa factory was one of the few in Europe specialising in buttons and openwork for the mode (so-called filigree, similar to wirework, where the other side of the plate shows through), and from here it spread to Germany, the UK and the USA, as well as to Japan and Saudi Arabia.

Under the Czechoslovak Republic’s communist-era state-owned company Kohinor Dečin, Tyssa products could be purchased until 1993; after privatisation in 1991-1993, the factory was again divided into several companies, some of which have disappeared, but the departments carrying on the tradition are now part of the new TYSSA. In the democratic world, the company will continue as the current TYSSA METAL company. And in the northernmost Czech city of Šrknov, in a beautiful building that was once a theatre, metal buttons are still being manufactured today.

・Handwork and its traditions, still the same in 2023

Two hundred and fifty years after the first tin button, what has actually changed in the 21st century in metal button production in North Bohemia?

The overall quality of the product has improved – production has been accelerated, the range of surface treatments to prevent rust and deterioration has been expanded, and the product now complies with strict EU health and safety standards – but everything else has remained the same: the use of Czech raw materials and the handmade craftsmanship of the Czech people. If you hold a metal button from 1920 in your hand and a metal button made this year, you will not notice the difference of 100 years. This is because beautiful Czech metal buttons are produced with the same attitude that has been in use for generations.

・The manufacturing process

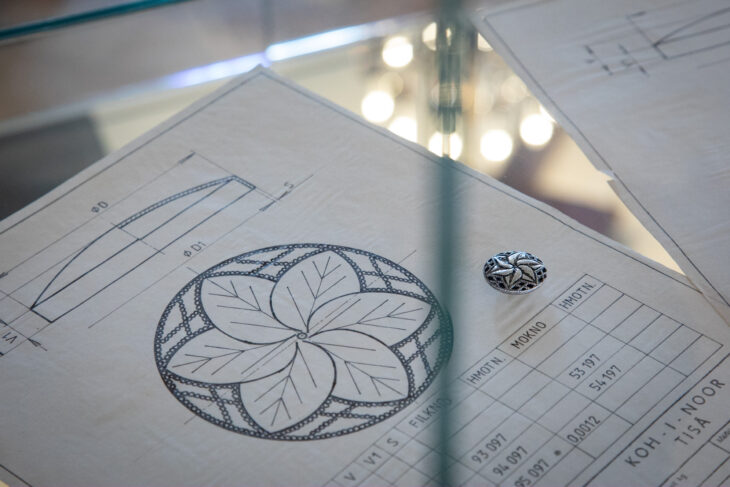

Traditional industries that have been in existence for a long time often have the same basic manufacturing process as in the past, with human hands and their skills being the foundation of the manufacturing process. The first step is to create the button design on the desk and then make the stamping die.

This is a blueprint of a design made during the days of the former state-owned company Kohinoor.

This is not a push-mould for a button, but a craftsman, who is also an engraver, is making the push-mould for attaching the pattern to the tin plate that will become the button by hand. This is a very detailed process that requires skilled workmanship. This produces a concave template (凹 form) that can be used to produce a lot of buttons worldwide. After checking the mother mould (凹 form), a convex mould father mould (凸form) is produced.

This is a very old metal button press mould – TYSSA METAL has a large collection of moulds that are more than 100 years old.

The thread like spools are tin strips. The button motif is cast onto this metal strip. The metal is inserted between the pressing moulds (convex and concave) and the pattern of the mould is pressed into it. Automatic presses or compression presses are used for this operation. Small assistants are used for detail work.

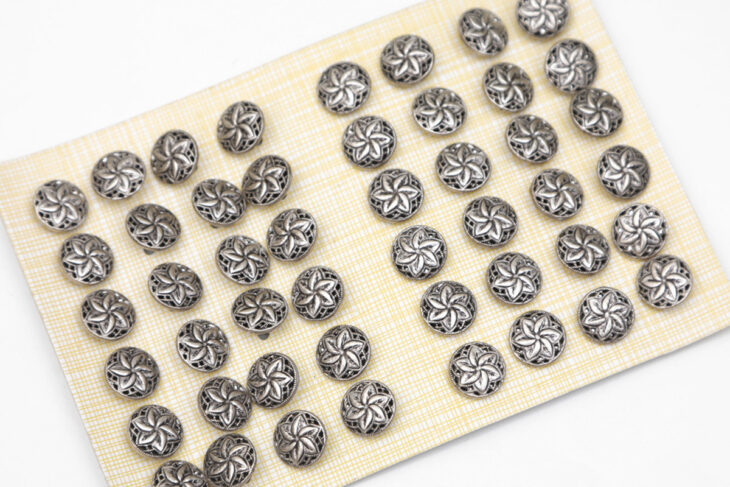

This is the top of a cast and punched metal button. Invariably, a convex (mother) and a concave (father) mould are used to cast these delicate patterns into the thin metal plate. The more delicate the engraving, the more delicate the pattern, so this mould alone shows the high level of skill of Bohemian craftsmen.

The metal button is finally formed when the upper and lower halves of the button are joined together in the press. But a long process awaits after this. First, the button is degreased, then the surface is treated in a galvanising bath. Some buttons are also coloured or gilded by hand. Alternatively, metal buttons are finished with a special abrasive. The surface is then treated to a matt finish or a texture that is both rough to the eye and to the touch. Finally, the zinc plating is repainted to keep it stable and prevent wear, where it is finally completed.

In each process, the human hand measures, feels and visually checks the details, and the work continues. The finished metal button has gone through so many processes that it is hard to imagine from just looking at it. The very last process is the quality check before shipping. This is a process that is carried out completely by hand and eye. No machine, no matter how accurate, can beat the senses of a human being in this process.

・The link between generations

Metal button making has passed through many generations and continues to this day. Like any other traditional craft, many hands are involved. In the world of metal buttons in Bohemia, there are designers, mould carvers, pressers and platers, as well as those who assemble the tin plates that become the buttons, those who inspect them… The beautiful buttons are the result of the hard work of these people.

North Bohemia is considered to be one of the poorest regions in the Czech Republic. Every day from early in the morning (it is not unusual for factories in the region to start work before 4am). The work is highly concentrated and nerve-wracking, and, so to speak, the same work is repeated day after day. Despite the high level of skill, the average income is not very high. Succession is also a common problem in the Czech traditional crafts world. Nevertheless, craftsmen consciously and unconsciously know how much weight their work carries as a whole. In the long, long history of manufacturing, it is not only skills that human hands have learnt, taught, mastered and passed on to the next generation. The mysterious power that resides in the objects pushes the craftsmen involved and fascinates those who pick them up.

・Conclusion

There is a saying that the Czechs are the people with golden hands. The Czechs have an established reputation for their ability in design, backed up by history, as they have also shown the world their versatility in the world of graphic design. Czech film posters, the design of Czech postage stamps and illustrations for Czech picture books, for which eminent graphic designers have been in charge, are not too much to explain for fans of the Czech Republic in the world. The same can be said for the world of metal buttons. It’s only a button, but it’s a button… The playfulness, spirit and age-old message contained in a few centimetres of metal have been delivered to the world for 250 years, backed up by the diligent work of various craftsmen and women.

Currently, TYSSA METAL is the only company in the Czech, producing metal buttons. If you are interested in selling or buying our products, please contact us and we will provide you with detailed information.

Website: TYSSA METAL

Contact:contact@babovka.com

Writer: Antique shop [Babovka]